Agricultural & Slurry Waste Separation

Linton Solution are experts in Agricultural & Slurry Waste Separation Northern Ireland & UK wide. We offer a wide range of waste separation solutions including our CARIER Separator, Screw Press Separators & Centrifugal Separators Northern Ireland & UK wide. Please see below for further details.

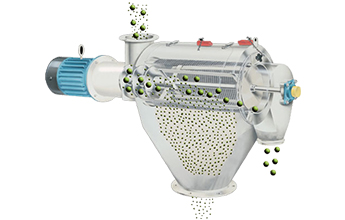

Centrifugal Separators Northern Ireland

Centrifugal separators are machines which uses centrifugal force, gravity, and mechanical means to separate compounds. A centrifugal separator can separate liquid-liquid mixtures, liquid-solid suspensions, gas-liquid/solid mixtures, and other particles by specific gravity. Material is fed into the feed inlet and redirected into the cylindrical sifting chamber by means of a feed screw. Rotating, helical paddles within the chamber continuously propel the material against the screen, while the resultant, centrifugal force on the particles accelerates them through the apertures. These rotating paddles, which never make contact with the screen, also serve to breakup soft agglomerates. Over-sized particles and trash are ejected via the oversize discharge spout.

CARIER -THE ENVIRONMENTAL AND ECONOMIC

SOLUTION TO SLURRY HANDLING

The Carier Separator combines screening and dewatering in one

machine. It brings management, flexibility and control, while utilising

a valuable farm resource to the economic benifit of the farm business.

Capable of separating slurries of all consistencies and ages the Carier

is suitable for separation of liquids and solids in a wide range of waste

products found on dairy and pig farms, sewage works, abattoirs,

cattle markets, food processing plants, water utilities, breweries etc.

Stainless steel construction ensures a prolonged life, reliability,

durability and efficiency. the result is a separator with minimal

maintenance requirements, large processing capacity and optimal solids separation.

SEPARATOR FEATURES:

• The carier is available in two sizes, the rs1 000 uses a separating screen

1.0m in length while the rs400 model uses a screen size of 0.4m in length.

• 50% drier cake than conventional static screen systems.

• Separation of slurries with dry matter up to 15%.

• More cost effective throughput than centrifugal or screw press designs.

• Stainless steel, rubber and high-density polymer materials mounted

robust frame suitable for the harsh farm environment.

• Rolling contact points with rubber and polymers against stainless steel for less

wear, maintenance, downtime and repairs.

• Manual or automatic washdown system extends the life of the unit.

• Intelligent weir box and overflow unit prevents overfeeding and provides

stone protection.

• Internal splash guards and seals to protect components.

• Platforms, gantry and access ladders galvanised to en1461.

• Low power consumption.

SEPARATED LIQUIDS:

• Are free flowing and can be pumped through small bore piping.

• Can be spread by conventional tanker.

• Can be distributed through an irrigation system.

• Can be stored without the formation of a crust or heavy sediment.

• Have 20% to 30% less volume than the original slurry, reducing the

requirement for storage capicity.

• Can be used as part of a flush cleaning system.

• Form a valuable organic fertiliser.

• Significant reduction in odour/smell.

• Rapidly penetrates the soil when spread and does not cap the surface

with solids

• Livestock will graze herbage within days of application.

• Suitable for subsequent or complete treatment systems.

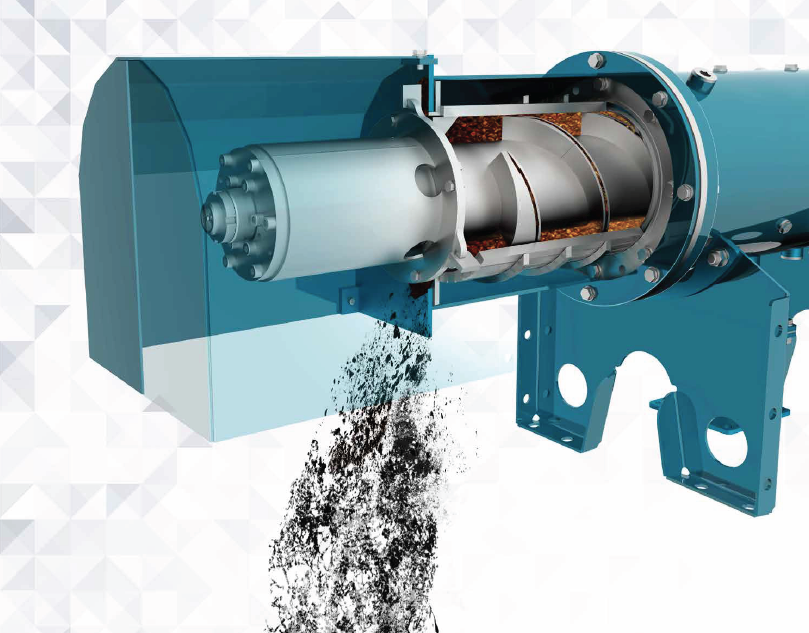

Screw Press (BÖRGER)

We offer a range of screw press separators used for the processing of livestock slurry, biogas, and civil/industrial effluents. They feature a screen inspection window, screw treatment, screens, planetary gearbox, side supported screw front, sealing system, sealing inspection window, and smart piping input.