Börger Products

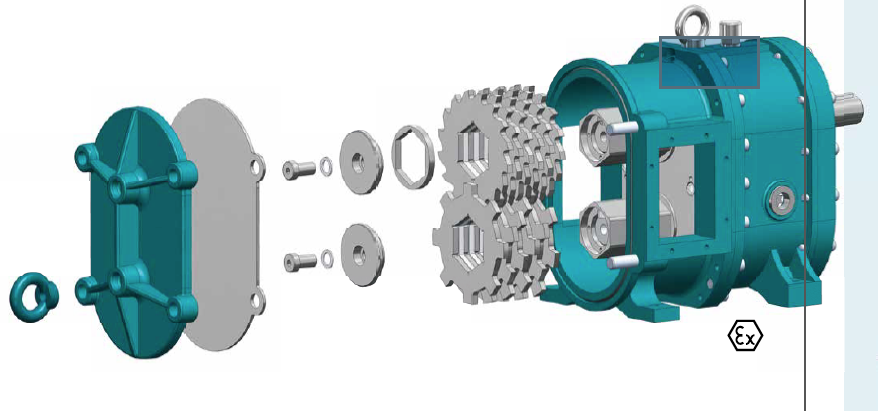

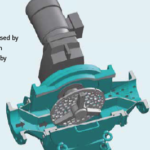

Börger Rotary Lobe Pump

Borger Rotary Lobe Pumps are made of few individual parts. Instead of adopting the widely used segmented pump design, the different size casings and rotors are manufactured in a single-piece construction. The result: robust and compact Rotary Lobe Pumps characterized by quiet, safe and reliable operation, long service life and excellent ease of maintenance.

Wear parts can be quickly accessed or replaced by operation and maintenance staff, without the removal of piping or drive systems.

This kind of simplicity is B.rger’s principle. The B.rger Rotary Lobe Pump features a cantilevered shaft design. The pumps can be arranged in a variety of mounting positions and

are suitable for multiple drive types including electric motors, combustion engines and hydraulic motors. Even complete mobile units pose no problem and are manufactured in

company-owned workshops.

Borger Rotary Lobe Pumps are self-priming, valveless, positive displacement pumps. Rotors, synchronized by the timing gear, are fastened to two parallel shafts rotating in opposite direction. As the rotor pair counter rotates, a cavity is created at the suction side. The resulting chamber fills with the pumped fluid.

The medium is conveyed between lobe surfaces and the surrounding pump casing and then displaced into the casing opening at the discharge side. The flow direction can easily be reversed by changing the direction of rotation. Borger Rotary Lobe Pumps are therefore very well suited for reversing operation.

Börger Multicrusher Northern Ireland

The Multicrusher is an effective, universally applicable macerating unit based on the proven design of the Börger Rotary Lobe Pump. The cantilevered shafts, bearings, shaft seals and casing are identical to the Rotary Lobe Pump which means you can rely on the robust technology and, above all, on the unmatched ease of maintenance!

If you already have a Börger Rotary Lobe Pump installed, you will be able to use many of the same consumables for your Multicrusher. Both the Börger Rotary Lobe Pump and the Multicrusher share the same unique MIP advantage: MIP (Maintenance in Place) means that all wear parts can be replaced on-site by operating personnel without the removal of pipe or drive systems.

This unmatched ease of maintenance guarantees low costs and short downtimes! Whether you integrate the Multicrusher into a pump circuit or use it as a standalone device – its flexibility is unique! Quick access to the blades permits a situation dependent blade selection and thus variable cut qualities: The required particle size can be achieved by selecting different blade combinations, blade tooth profiles and blade thickness

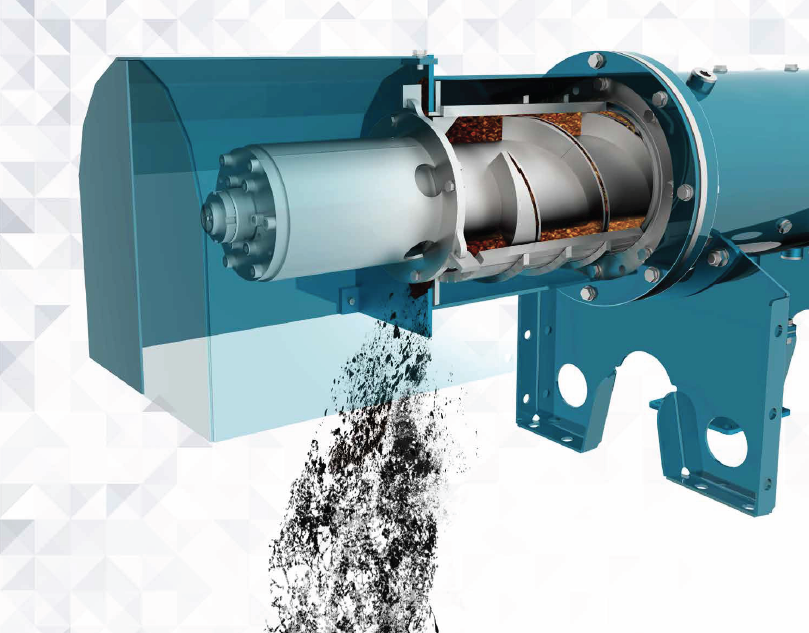

BÖRGER BIOSELECT Screwpress Separator

OPERATING PRINCIPLE

The media to be separated find their way through the inlet opening into the vessel-like Bioselect. The outer cylinder is separated from the auger by a roundly sealed wire-wound screen pipe. The auger has a frictional connection to the drive. The imported liquid flows into the screen area next to the drive. The liquid flows through the wedge wire screen into the outer vessel area. The liquid drains through the liquid outlet .

The solid contents remain on the screen surface. They are conveyed into the press channel by the rotating auger. Powerful subsequent dewatering takes place in the press channel . The rotating auger has a Multi Disc (sealing disk), which can be shifted in axial direction, at the non-drive end. The adjusting unit presses the Multi Disc against the auger and the compressed thick matter plug. When the thrust force of the plug is greater than the spring force of the Easy Shift unit , a slot for discharging is created by axial movement. A scraper edge is used to loosen and expel the solids.

AUGER WITH PROFILE GROOVE

Fibers are caught in the profile groove of the auger . The fibers function as a sealing brush. Metallic rubbing between the auger and the wedge wire screen (2) is avoided by the brush. This unique technology increases the service life of the wedge wire screen and auger many times over. In addition, the brushing surface cleans the wedge wire screen very thoroughly. Additional cleaning by the operator is not necessary.

INSTALLATION OPTIONS

The installation options of the Bioselect are as versatile as their requirements. Whether attached to a simple wall bracket, installed on a movable frame with an upstream macerator or as a mobile version with a conveyor belt – the application options of the Bioselect are unique. Several separators can be installed next to each other – also as mobile versions – for very high separation quantities.

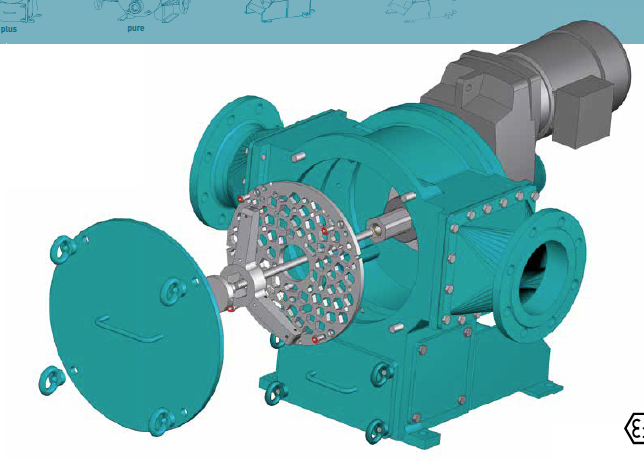

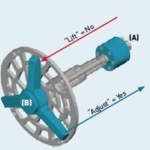

Börger Multichopper

The Börger Multichopper incorporates advantageous technical and operational design features. The preloading of the multi-vane blade is adjusted from outside the unit. A special technology ensures that the axially fixed blade is pressed against the perforated disk which can be used from both sides. The shaft seal is supplied as a mechanical seal as standard. The Multichopper incorporates Börger’s well-known maintenance-friendly design. All macerating elements can be removed from their positions by releasing

a single clamping unit situated on the outside of the device. No special tools are required for making adjustments or performing service operations. The B.rger Multichopper

is available in two designs: The Multichopper plus is equipped with a debris collector for solids which cannot be macerated, while the Multichopper pure is designed to have no cavities in which the medium can become entrapped. Hence the Multichopper pure is built without a debris collector. The Multichopper is available in gray cast iron and stainless steel materials.

A well thought-through system developed by practitioners.